Copper is prized in various industries for its conductivity and versatility, but one problem plagues it—oxidation. Left exposed, copper wires can quickly degrade, especially in humid or saline environments. This is where tinned copper wire shines.

Known for its corrosion resistance and durability, tinned copper wire is essential in industries such as electronics, marine, and industrial settings. But what is tinned copper wire and why it is gaining so much importance? Let us find out!

What Is Tinned Copper Wire

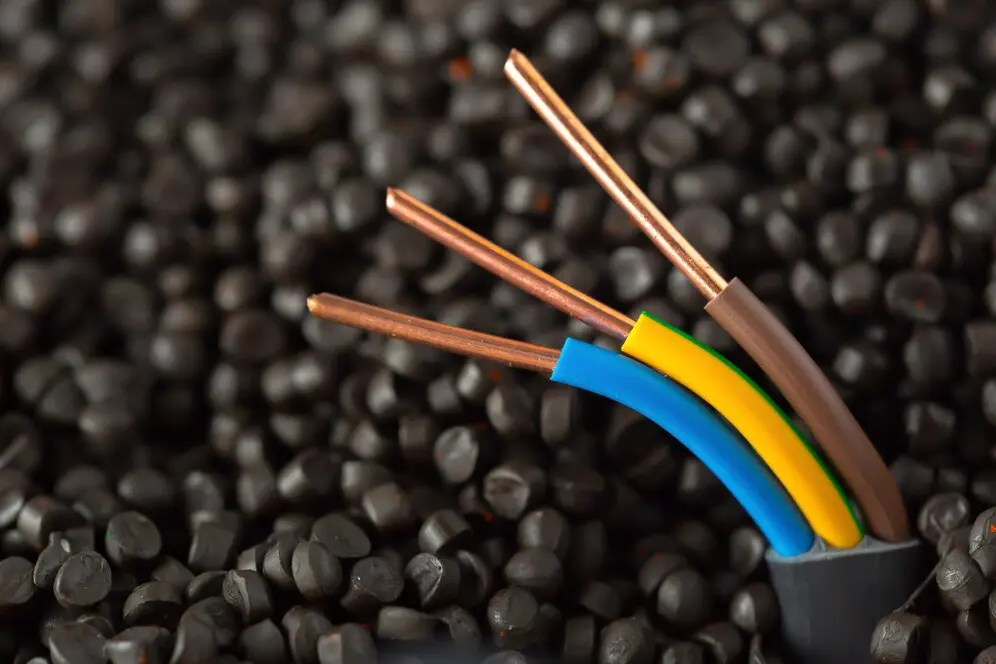

Tinned copper wire is an uninsulated copper wire with a thin layer of tin coating. These wires are highly valued for their durability and enhanced corrosion resistance.

From electronic components, wastewater and marine applications to jewellery productions, tinned wires can be found in many industries.

But why?

This is because the tinning process not only preserves the wire’s conductivity but also extends its lifespan, making it ideal for challenging environments where bare copper may corrode quickly.

Here’s a closer look at its standout features:

- Corrosion Resistance: Unlike bare copper wire, tinned copper is better suited for humid or saline environments, reducing oxidation over time.

- Superior Durability: The tin coating acts as a shield, significantly enhancing the wire’s lifespan even in challenging environments.

- Versatile Applications: Found in electronics, jewellery, marine, and industrial environments. It is ideal for systems prone to moisture or pollutant exposure.

SV Electricals specializes in high-quality copper products, ensuring reliability and performance across various applications. You can check out our product range to get a better idea.

What Does Tinned Copper Wire Mean In Electrical Terms?

In electrical terms, tinned copper wire refers to a copper conductor coated with tin. This coating process preserves the copper’s electrical conductivity while protecting the wire from oxidation. Tinned copper wires are especially valuable in high-moisture applications where standard copper wires would degrade over time.

What Is Tinned Copper Wire Used For

Tinned copper wire is widely used for its durability and resistance to corrosive conditions, making it a preferred choice across several industries. Here’s a closer look at its applications:

Electronics

Tinned copper wire is essential in electronics, particularly connecting circuit board components. It offers superior conductivity, reducing the risk of corrosion over time. This makes it ideal for devices that demand reliability, from consumer gadgets to specialized industrial equipment.

Jewelry Making

Due to its malleability and aesthetic appeal, tinned copper wire is popular in jewellery production. Artisans use it to create intricate, durable designs that withstand wear and exposure. Tinned copper’s silvery coating enhances its visual appeal, making it ideal for unique, eye-catching pieces.

Marine and Industrial Settings

In harsh environments like marine settings or industrial plants, tinned copper wire helps in –

- Resisting damage from saltwater, gas, and oil

- Protecting wiring systems from corrosive elements

- Extending their lifespan and reducing maintenance needs.

Wastewater Treatment Facilities

Tinned copper wire is extensively used in wastewater treatment facilities, where copper is often exposed to water and other corrosive agents. The tin coating provides a protective barrier, ensuring that the wires remain functional and require minimal maintenance despite the harsh environment.

Underground Subway Systems

In subway systems, durability is critical due to constant exposure to moisture and pollutants. Tinned copper wire is commonly used in these environments for its ability to withstand such challenges, ensuring reliable electrical connections and reducing system failures.

Automotive Use

Car wiring often needs durability due to temperature changes, vibrations, and exposure to moisture. Tinned copper is a great option here for extended longevity.

Benefits Of Tinned Copper Wire

Tinned copper wire has several benefits, including:

- Corrosion Resistance: Unlike plain copper, tinned copper withstands moisture and salty conditions, making it ideal for marine or outdoor use.

- Longer Lifespan: The tin coating protects the copper inside from rust and wear, extending the wire’s life even in damp or harsh environments.

- Consistent Conductivity: Tinned copper conducts electricity just as effectively as regular copper, so there’s no trade-off in performance.

- Flexibility: Tinned copper wires are easy to bend and mould, making them great for electronics, automotive, and DIY applications.

- High Heat Tolerance: These wires can handle temperature changes better, making them a good choice in vehicles and industrial settings with fluctuating temperatures.

- Easy to Solder: The tin layer allows tinned copper wires to be soldered quickly, which is helpful for secure, lasting connections in electronics and other setups.

- Thermal Resistance: In applications with temperature fluctuations, like industrial cranes or heavy machinery, tinned copper remains stable, preventing degradation from thermal stress.

Difference Between Copper And Tinned Wire

Did you know tinned copper wire can last up to 10 times longer than bare copper in corrosive environments? But what exactly is the difference between the two? Find out below.

Features | Bare Copper Wire | Tinned Copper Wire |

Corrosion Resistance | Minimal | High |

Lifespan in Harsh Environments | Short | Long |

Applications | Indoor, low-moisture environments | Electronics, marine, industrial, and jewellery |

Maintenance | Needs frequent checks in certain environments | Low maintenance |

Price | Lower | Slightly higher |

For a detailed comparison, you can visit our guide on the differences between tinned and bare copper wire.

Difference Between Annealed Copper And Tinned Copper

Annealed copper is known for its flexibility due to its heat treatment process. In contrast, tinned copper retains the conductive properties of pure copper while offering enhanced corrosion resistance.

While both types are flexible, tinned copper is better suited for applications exposed to harsh conditions.

Is Tinned Copper Wire More Expensive Than Other Copper Wires?

Yes, tinned copper wire costs more than bare copper due to the additional tinning process. Material and manufacturing expenses are higher, as tin is a pricier element.

However, this extra investment is worthwhile for applications exposed to harsh environments. While bare copper is economical, tinned copper pays off in the long term by reducing maintenance and replacement costs.

What Are The Physical Properties Of Tinned Copper Wire?

By now, you must have an understanding of what is tinned copper wire. But how do you tell if a wire is tinned or not? So, here we have broken down some physical properties and characteristics of tinned copper wire to make it easy for you to check whether a wire is tinned.

- Visual Inspection: Look for a shiny surface; tinned copper generally has a lustrous finish compared to dull bare copper.

- Conductivity Test: Tinned wires maintain good conductivity, but it might be bare copper if you notice significant resistance while testing.

- Soldering Test: If solder flows easily and adheres well, it likely indicates tinned copper. Bare copper may require extra effort to heat and solder.

- Magnetic Properties: Tinned copper wire is not magnetic.

- Thickness range: The thickness of the tin coating on tinned copper wire typically ranges from 1 to 5 microns. The more the thickness, the better the protection from corrosion.

- Colour Comparison: Tinned wires appear silvery or greyish. Thanks to the tin coating, the wire is more polished. Bare wires, on the other hand, display a reddish-brown colour.

Is Tinned Copper A Good Conductor And Is It Safe?

Yes, tinned copper is a decent conductor of electricity, but it’s not as good as pure copper.

Pure copper tops the list for conductivity, allowing electricity to flow easily. Tinned copper does a pretty good job too, maintaining about 90-95% of pure copper’s effectiveness. The tin coating helps protect against corrosion, making tinned copper great for moist or harsh environments where regular copper might fail.

When it comes to safety, tinned copper shines. The tin layer prevents oxidation, which means it can maintain its performance and reduce the risk of short circuits. This is especially valuable in marine settings or industrial areas where wires can be exposed to water and other potentially damaging substances.

As for whether tinned copper is an alloy, it’s not. It’s still primarily copper, just with a protective layer of tin. And most tinned copper wires are lead-free, making them safe to use in various applications.

So overall, while tinned copper isn’t quite as conductive as pure copper, it offers great reliability and safety for many different uses!

How Durable And Corrosion-Resistant Is Tinned Copper Wire?

Tinned copper wire stands out for its impressive durability, especially in moisture-rich environments. When the wires are dipped and coated, they become resistant to rust and oxidation. It’s like an SPF of wires.

Take the Statue of Liberty—its copper structure was originally bright and shiny. However, due to oxidation, a protective green patina was developed on its surface. While that’s a different scenario, it highlights the importance of protective coatings in preserving metal integrity over time.

Is Tinned Copper Wire Flexible And Easy To Work With?

Tinned copper wire is highly flexible, making it a go-to choice for projects that need a lot of movement or adjustments. Tin, being softer than copper, also makes the soldering process less demanding for tools, enhancing overall workability.

Unlike solid copper, tinned copper (especially in stranded form) can bend and flex without breaking. This flexibility makes it ideal for dynamic environments where wires are often repositioned.

Standout Features of Tinned Wires:

- Adaptability to environmental conditions

- Durable and Cost-effective solutions

- Protection against Corrosion and oxidation

- Allows for easy and smooth soldering

- Same Conductivity as Bare Copper

Frequently Asked Questions About What Is Tinned Copper Wire

How Can You Use Tinned Copper Wire

Here’s what is tinned copper wire used for:

- Automotive Wiring

- Underground systems

- Marine & subway systems

- Industrial Machinery

- Solar Plants

Is Tinned Copper Wire More Expensive Than Bare Copper?

Bare copper wire is copper without any coating. However, tinned copper wire is slightly more expensive due to its tin coating that provides a protective barrier against oxidation.