Cable tray are essential components in electrical and telecommunications installations, providing a practical solution for cable tray management in both commercial and industrial environments. They are designed to accommodate and support multiple cables, providing a systematic approach to wiring that prevents damage and facilitates easy maintenance.

What Is Cable Tray?

A cable tray is an essential component in electrical installations designed to support and organize electrical cables and wires.

Structure and Design

Cable trays are typically manufactured from metal or fiberglass and come in various designs to suit different applications and environments.

The main types of cable trays include:

- Ladder Tray: Consists of two parallel side rails attached to transverse rungs, resembling a ladder.

This design provides adequate ventilation and is ideal for heavy cables and high-density installations.

- Perforated Tray: Features a flat bottom with holes or perforations along the surface.

These trays allow for easy cable management and are suitable for medium to heavy loads.

- Solid Bottom Tray: Features a continuous solid bottom surface, protecting cables from physical damage and environmental factors.

These trays are used in situations where extra protection is necessary.

- Cable Duct: Enclosed trays with covers, often used in scenarios where aesthetics are important or where cables need to be concealed.

Primary Function

The primary function of cable trays is:

- Organize cables: Cable trays keep cables neatly organized, preventing tangling and reducing the risk of damage.

This organization helps in easier maintenance and troubleshooting of electrical systems.

- Support cables: They provide physical support for cables, distributing their weight evenly and reducing the stress on individual cables and connections.

This support is important in preventing cables from coming loose and causing potential damage.

- Facilitate cooling: By allowing air to circulate the cables, cable trays help dissipate the heat generated by electrical currents, which increases the performance and lifespan of the cable.

- Increase safety: Proper cable management reduces tripping hazards and protects cables from environmental factors such as moisture, dust, and mechanical impact.

- Simplify upgrades: With organized and accessible cable routing, modifications or additions to the electrical system can be made more efficiently.

How Many Types Of Cable Trays Are There?

Ladder-Type Cable Tray

Design and Construction: Ladder-type cable tray have a ladder-like design with two side rails attached to transverse poles.

This design allows easy installation of cables and provides excellent support while maintaining ventilation.

Advantages:

- Ventilation: The open design allows for optimal air circulation, which helps cool the cables and prevent overheating.

- Access: Cables can be easily installed, maintained, or replaced due to the open structure of the tray.

- Strength: The ladder design provides high load-bearing capacity, making it suitable for heavy cables.

Common Uses: Ladder-type cable trays are commonly used in industrial environments,

commercial buildings, and areas where high load-bearing and ventilation are important.

They are particularly useful in locations where cables require frequent access or maintenance.

Perforated Cable Tray

Design and Construction: Perforated cable tray are characterized by their perforated base, which allows for the easy passage of air and water.

The tray has some holes or slots to facilitate this.

Benefits:

- Ventilation: Perforations in the tray promote airflow, which helps cool the cable and reduce the risk of overheating.

- Flexibility: The perforated design allows for the easy addition of cable supports and accessories.

- Cost-Effectiveness: Generally, perforated cable trays are more economical than other types due to their simple design and manufacturing process.

Applications and Typical Environments:

- Commercial Buildings: They are often used in commercial buildings where moderate cable management is required.

- Data Centers: In environments where cooling is important, such as data centers, perforated trays help effectively manage cable heat dissipation.

Solid Bottom Cable Trays

Design and Construction: Solid bottom cable trays have a continuous, flat surface that completely encloses the cable.

This design prevents debris from falling onto the cable and provides additional protection.

Use Cases:

- Protection: Solid bottom tray are ideal for environments where cables require protection from falling debris, chemicals, or other contaminants.

- Security: The enclosed design provides superior protection for sensitive cables and wiring.

Why Choose Solid Bottom Cable Tray:

- Increased Protection: They provide a secure environment for cables, protecting them from external factors.

- Clean Appearance: The solid bottom ensures a neat appearance and reduces the likelihood of cables becoming tangled.

Why Perforated Cable Tray Is Used?

Why Perforated Cable Tray Are Used?

Perforated cable tray are used for several reasons:

- Ventilation and heat dissipation: The perforated design facilitates better airflow around the cables, helping to dissipate heat and maintain optimal operating temperatures.

- Flexibility and ease of installation: Perforations allow cable accessories to be easily added, providing flexibility in managing and adjusting cable layouts.

- Maintenance and access: The open design makes it easy to access and maintain cables, reducing the time and effort required for troubleshooting and repairs.

- Cost-effectiveness: Perforated cable tray are often more affordable than solid-bottom trays and can be used in a variety of applications at no additional cost.

What Are The Different Materials Used For Cable Trays?

FRP Cable Tray

What is FRP Cable Tray?

FRP (Fiberglass Reinforced Plastic) cable trays are made from a composite material combining fiberglass with a plastic resin.

This material is known for its excellent strength-to-weight ratio and resistance to various environmental factors.

Material Properties and Benefits:

- Corrosion Resistance: FRP cable trays are highly resistant to corrosion, making them ideal for use in environments such as chemical plants, offshore facilities, and wastewater treatment plants.

- Durability: They offer high strength and durability, with the ability to withstand impacts and mechanical stresses.

- Lightweight: Compared to metal trays, FRP trays are significantly lighter, easing handling and installation.

- Fire Resistance: FRP materials are generally fire-resistant, adding a layer of safety in fire-prone areas.

Industries Where FRP Trays Are Preferred:

- Chemical Industry: Due to their resistance to corrosive substances.

- Marine and Offshore Applications: For their ability to withstand saltwater and harsh marine conditions.

- Wastewater Treatment Plants: Their resistance to chemicals and high durability make them suitable for these environments.

GI Cable Tray

What is GI Cable Tray?

GI (Galvanized Iron) cable trays are made from iron coated with a layer of zinc to prevent rust and corrosion.

The galvanization process involves dipping the iron trays into molten zinc, which forms a protective layer on the surface.

Galvanization Process:

- Hot-Dip Galvanization: The most common method where trays are immersed in molten zinc. This process creates a thick, durable coating.

- Electro-Galvanization: An electrochemical process where zinc is applied as a thin layer. It offers less protection compared to hot-dip galvanization but is used in less demanding environments.

Corrosion Resistance:

- High Resistance: The zinc coating provides excellent protection against rust and corrosion, making GI cable tray suitable for indoor and outdoor use in moderately aggressive environments.

Typical Application

- Commercial Buildings: Often used in office buildings and retail spaces.

- Industrial Settings: Suitable for manufacturing and assembly plants where environmental conditions are controlled.

PVC Cable Tray

What is PVC Cable Tray?

PVC (Polyvinyl Chloride) cable tray are made from a type of plastic known for its chemical resistance and lightweight properties.

PVC tray are used in various applications where corrosion resistance and cost-effectiveness are critical.

Characteristics:

- Cost-Effectiveness: PVC trays are generally less expensive compared to metal or FRP tray, making them a budget-friendly option.

- Corrosion Resistance: They are resistant to most chemicals, including acids and alkalis, though they may not be suitable for high-temperature environments.

- Ease of Installation: The lightweight nature of PVC trays makes them easy to handle and install.

Suitable Environments:

- Indoor Use: Ideal for use in dry and indoor environments where chemical exposure is limited.

- Residential and Light Commercial Applications: Commonly used in homes, schools, and small office spaces due to their cost-effectiveness and ease of installation.

What Are The Applications Of Cable Trays?

Cable trays Different applications of cable trays help in selecting the right type for specific needs. Here is a detailed look at their applications:

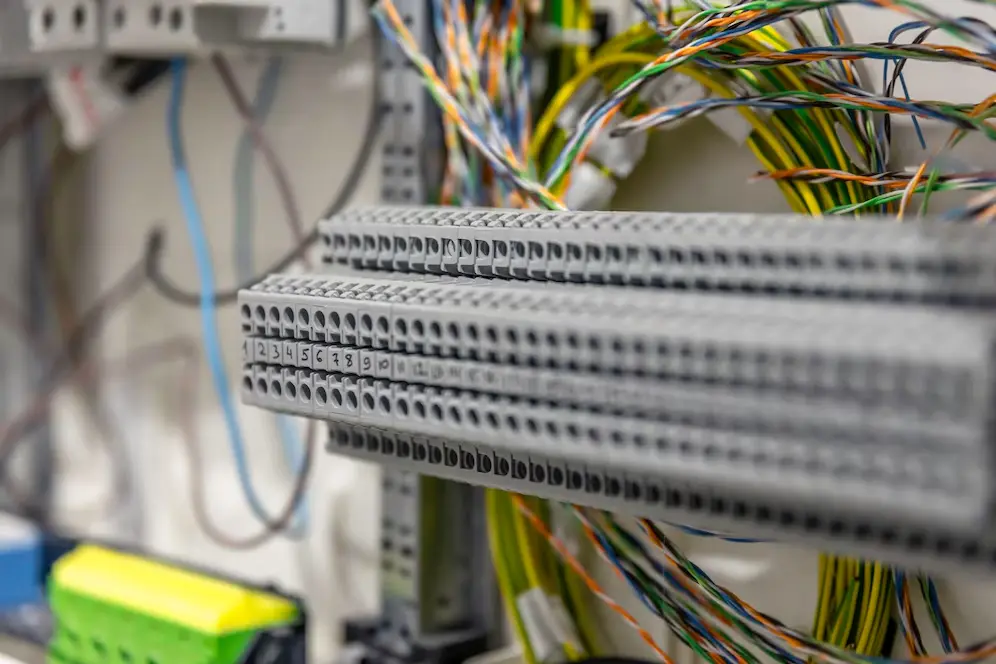

Industrial Use Cases

In heavy industries, cable trays play a vital role in managing extensive networks of electrical cables.

They are commonly used in environments where large volumes of cables need to be efficiently routed and protected.

Industrial use cases of cable trays include:

- Efficient Cable Management: Cable trays help organize and support large volumes of cables, preventing entanglement and damage.

They also ensure that cables are accessible for maintenance and repair.

- Safety and Compliance: Industrial settings often require adherence to stringent safety standards.

Cable trays provide a safe route for cables, minimizing hazards related to exposed wires and ensuring compliance with safety regulations.

- Durability: Given the conditions in many industrial environments, robust materials such as FRP cable trays (Fiber Reinforced Polymer) are often used.

FRP cable trays are corrosion-resistant and suitable for chemical or moisture environments.

Commercial Installations

In commercial buildings, cable trays are essential for maintaining an organized wiring system that supports a variety of technical and electrical requirements.

Their applications in commercial settings include:

- Organized Wiring Systems: Cable trays help organize power cables, networking cables, and other types of wiring within commercial spaces.

This organization aids in easy installation, troubleshooting, and future upgrades.

- Flexibility and Expansion: Commercial installations often require flexibility to accommodate

future changes. Perforated cable trays are particularly useful in these scenarios. Perforated cable trays allow for easy modification and expansion of wiring systems without requiring extensive alterations.

- Aesthetic and practical benefits: Cable trays in commercial settings are designed to blend with the aesthetics of the building while providing a practical cable management solution.

They help maintain a neat and professional appearance.

Residential applications

Although less common, cable trays can also be used in residential projects for specific purposes:

- Home office: In a home office setup, cable trays can help manage and hide the many cables from computers, routers, and other devices, helping to keep the workspace looking neat.

- Custom installations: For custom residential installations, especially in high-tech homes with advanced wiring needs, cable trays can provide a solution to organize and protect cables.

Why Use A Cable Tray System For Cable Management?

Efficiency in cable organization

Cable trays provide a highly organized and efficient solution for managing and routing cables.

By providing a structured system, cable trays help streamline the placement of electrical wires and data cables.

The tray system supports cables of various types and sizes, preventing them from becoming tangled or disorganized.

Safety and Compliance

Cable trays play a vital role in maintaining safety and ensuring compliance with electrical standards.

Loose or poorly managed cables can pose significant hazards, including tripping risks and potential fire hazards due to overheating.

By keeping cables securely in place, cable trays reduce the risk of such accidents.

Cost-effectiveness

Investing in a cable tray system can be a cost-effective solution in the long run.

By improving cable organization and accessibility, cable trays reduce the likelihood of costly maintenance issues caused by tangled or damaged cables.

They also simplify the process for future expansion or modification, as cables can be easily added, not only saving labor costs but also increasing the overall reliability of the power system.

What Is The Purpose Of A Cable Tray Cover?

Cable tray covers serve several important functions in both commercial and industrial

Setting.

Here is a detailed look at their primary purposes:

Protection from environmental factors

Cable tray covers are essential for protecting cables from various environmental hazards. They protect cables from:

- Dust and debris: In environments where dust and debris are common, such as manufacturing facilities or construction sites, cable tray covers help keep cables clean.

Accumulation of dust can cause cables to overheat or impede cable performance. Covers prevent these particles from settling on cables, thus ensuring their longevity and optimal performance.

- External damage: Covers also provide a barrier against physical damage.

For example, they protect cables from accidental impacts, scratches, or other types of mechanical damage that can compromise their integrity.

This is especially important in high-traffic areas where equipment or personnel may come into contact with cables.

Increased safety

Safety is a key concern in any installation involving electrical cables. Cable tray covers play a vital role in enhancing safety:

- Preventing accidental contact: One of the main purposes of cable tray covers is to prevent accidental contact with live wires.

Exposed cables pose a significant risk of causing an electric shock or short circuit.

By covering the cables, these covers help reduce the risk of accidental exposure, ensuring that only authorized personnel handle or access the cables.

- Reducing trip hazards: Areas where cables are laid on the floor or in open trays present a tripping hazard.

Cable tray covers can help reduce this hazard by providing a smooth, safe surface on the cables, which can prevent trips and falls.

Aesthetic considerations

In addition to functional benefits, cable tray covers contribute to the overall appearance of a space:

- Clean and orderly appearance: For installations in visible or customer-facing areas, such as offices or retail locations, cable tray covers help maintain a clean and orderly appearance.

They hide unsightly cables and wiring, creating a more professional and aesthetically pleasing environment.

- Uniformity: The covers can also be matched to the color and design of the surrounding décor, helping them blend seamlessly into the overall design of the place.

This not only improves the visual appeal but also ensures that the installation complements the architectural style of the building.

Frequently Asked Questions About What Is Cable Tray

How Many Types Of Cable Tray Are There?

There are several types of cable trays, including ladder trays, perforated trays, solid bottom trays, and channel trays.

What Is The Difference Between Cable Tray And Cable Ladder?

A cable tray is a general term for systems used to support electrical cables, while a cable ladder is a specific type of tray with ladder-like steps designed to support heavy-duty cables.